Why Are Fit Tests Necessary?

In order for tight fitting respirators to provide the expected protection, they must seal properly to the user’s face. Air will take the path of least resistance, so if there is a leak in your respirator, there is a good chance you will be exposed to whatever is in your environment. Because of this, your respirator fit must be tested to ensure the respirator is working effectively.

Respirator fit testing is required by provincial laws in Canada and by Occupational Safety and Health Administration in the United States in order to ensure the respirator is indeed effective prior to going into hazardous atmospheres. In some cases, regulations will state that this needs to be repeated annually (e.g. British Columbia, OSHA), in Alberta, regulations refer to Canadian Standards Association (CSA) Z94.4, which states that fit testing should be repeated every two years. Other jurisdictions don’t specify an interval (e.g. Saskatchewan, Manitoba).

In addition to the local regulatory requirement, fit testing should be repeated whenever:

- a different size, model, or make of respirator is used, and/or

- any facial changes occur which could change the fit (e.g. weight gain or loss or dental work).

How Are Respirators Fit Tested?

There are two types of respirator fit testing. Qualitative fit testing uses an irritant smoke or odorous material and relies on the respirator wearer’s sensations (smell, irritation, taste) to give a pass or fail. Quantitative fit testing uses measuring equipment to measure the particle concentration inside and outside the respirator and calculates a numeric fit factor.

CIHC strictly adheres to CSA Standard Z94.4-11 for respirator fit testing to ensure that workers are wearing properly fitted respirators. We utilize the TSI Portacount respirator fit tester for quantitative fit testing. We ensure the respirator is appropriate for the hazards our clients face, and educate workers on respiratory protective equipment (RPE) maintenance and care.

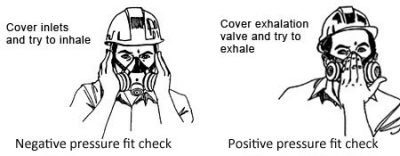

Once a respirator has been fitted to the individual, that individual must ensure that going forward they are using the same make, model & size of respirator (preferably the very same respirator they were successfully fit tested on) and that they perform their own fit checks (negative & positive checks, as demonstrated in the pictures below) each time they don it.

What Are the Limitations of Respirators?

It is of utmost importance that workers know the limitations of their respirators.

To begin with, in areas where the atmosphere is oxygen deficient or the concentration of the contaminant is greater than 50 times the exposure limit, the worker must work under supplied air as the protection factor of a full-facepiece air purifying respirator (APR) is exceeded at that level (according to CSA Standard Z94.4-11 assigned protection factors). A half-facepiece APR may be worn when the concentration is less than 10 times the exposure limit.

Note that the concentration of the contaminant in the workplace is best measured by having an Occupational Hygiene assessment completed under the direction of a Certified Industrial Hygienist or Registered Occupational Hygienist. This survey may require the use of exposure modelling, direct reading instrumentation, and/or collection of air samples for laboratory analysis. CIHC has extensive experience completing such surveys and we make sure to work closely with our clients to determine solutions to exposure risks including administrative controls, engineering controls and personal protective equipment such as chemical protective clothing and respiratory protection.

The cartridge type must be selected based on the contaminant! At times, when we go to work places, workers are found to be wearing cartridges which do not protect against the contaminant present in their work space. There is a false sense of security as they work in an area in which they are being exposed, thinking they are not. The SDSs for the products they work with need to be reviewed and the labels on the cartridges need to be checked to determine if those cartridges are indeed the cartridges which will protect against all of the expected contaminants.

Any questions about respiratory protection, or general concerns about contaminants in your workplace? Feel free to contact us via email at inquiry@cihc.info or call us at 403-543-3378.